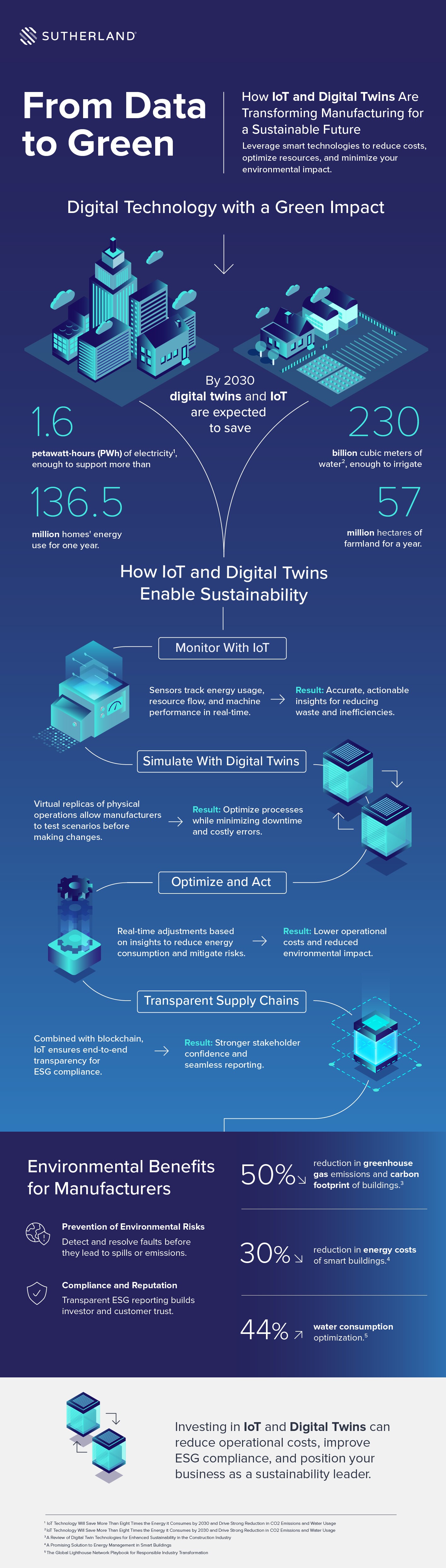

Harnessing IoT and Digital Twins for Sustainable Manufacturing – Manufacturers are turning to IoT in manufacturing and digital twin technology to build connected factories that are smarter, greener, and more resilient. Real-time data analytics from IoT sensors track energy use, water flow, and machine performance, helping enterprises cut waste and optimize resources. Digital twins simulate production processes, enabling predictive maintenance and safer scenario testing before costly changes are made. The result: operational resilience, higher energy efficiency, and measurable sustainability gains.

Reducing Carbon Emissions and Strengthening ESG Compliance – By adopting sustainable manufacturing powered by IoT and digital engineering, businesses can achieve up to a 50% reduction in greenhouse gas emissions, 30% lower energy costs, and 44% improvement in water optimization. Combined with blockchain, IoT ensures transparent supply chain visibility and ESG compliance, strengthening stakeholder trust and brand reputation. With decarbonization strategies and predictive insights, manufacturers are better positioned to lead in sustainable growth while driving long-term profitability.